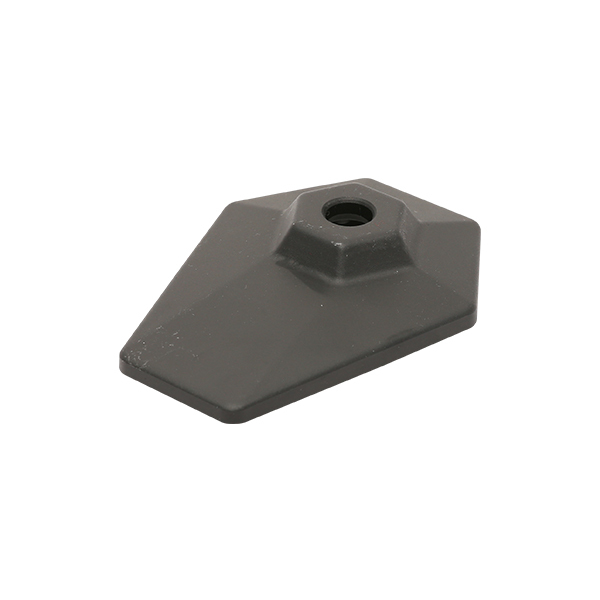

Forging electric bike forging, electric bike parts forging, motorcycle forging, motorcycle parts forgings

Forging: electric bike forging, electric bike parts forging, motorcycle forging, motorcycle parts forging

Welcome to DIko, a leader in the forging industry with 25 years of experience. With a physical production plant of 66,000 square meters, we provide high-quality, high-specification forged parts and accessories to customers in the electric vehicle and motorcycle industries. Our excellent service and deep experience have provided us with good relationships with many well-known companies.

We not only provide forging services, but also offer integrated services from drawing proofing to production after-sales to ensure product performance and quality, keep close cooperation throughout the production process and ensure customer satisfaction.

As an experienced forging company, we value the importance of the forging process, and for this reason, we are equipped with state-of-the-art production equipment and a technical team that can provide the best production solutions flexibly and efficiently according to the needs of different products. We are widely used in various industries and also provide quality services to customers such as electric car forging, electric car parts forging, motorcycle forging, motorcycle parts forging, etc.

In order to better meet the needs of our customers, we are constantly improving and enhancing our production technology and capabilities, and are committed to providing our customers with products that meet market demand and are better. Also, we firmly believe that in the future of forging industry, only quality and innovation can make a company successful. We will always maintain this quality service to meet the needs of our customers and the market.

Here, we pay great attention to the quality of our products and forging processes, using only the highest quality and optimized production processes to ensure the production of quality products. We have the flexibility and high productivity to meet the needs and specifications of a wide variety of customers. Our forged parts and accessories are of consistent quality and durability, while being able to offer fast production cycles to ensure better adaptation to market needs.

Thank you for reading! If you have any questions or needs regarding our products and services, please feel free to contact us and we will provide you with the best solutions.

-

PrevForging Scooter Forging, Scooter Parts Forging

-

NextNone