-

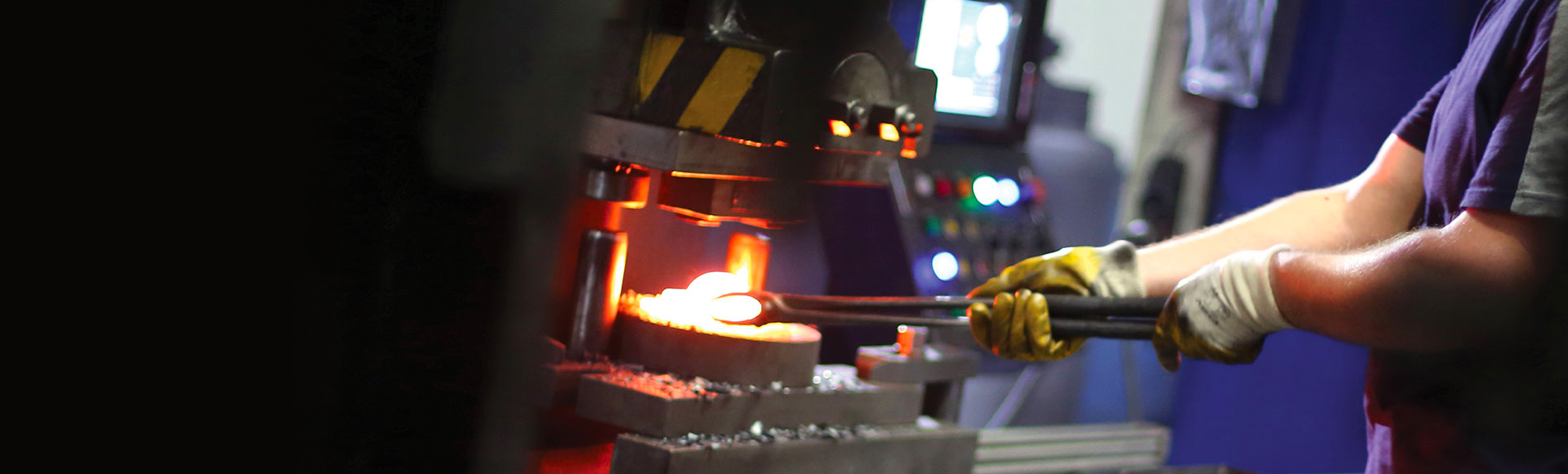

Forging advantage

Forging: It is a processing method that uses forging machinery to apply pressure to metal bad materials to cause plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes. One of the two major components of forging. The as-cast looseness and welding holes of metal can be eliminated by forging, and the mechanical properties of forgings are generally better than castings of the same material. For important parts with high load and severe working conditions in machinery, forgings are mostly used except for plates, profiles or weldments that can be rolled with simple shapes. Open forging (free forging). Using impact force or pressure to deform the metal between the upper and lower irons (stickers) to obtain the required forgings, there are mainly two kinds of manual forging and mechanical forging.

Material advantages

One-stop finished product customization factory

Forging materials are mainly carbon steel and alloy steel with various components, followed by aluminum, magnesium, copper, copper, etc. and their alloys. The original state of the material includes bar stock, ingot, metal powder and liquid metal. The ratio of the cross-sectional area of the metal before deformation to the area of the mold after deformation is called the forging ratio. Correct selection of the forging ratio has a lot to do with improving product quality and reducing costs. Forging has the effect of refining metal grains, so its strength is greater than that of castings

Technical advantages

A well-known forging factory in China, with multiple workshops and equipment, can forge various outer diameter products.

Possess forging machinery and equipment of various tonnages and 50 CNC machining centers.

The forging accuracy can reach between 0.1MM-0.2MM, and the precision tolerance of processing size (0.01MM-0.05MM)

Independent and complete 6S standard forging factory, independent CNC machining center area and subsequent surface treatment and other one-stop finished product customization factories

25 years of precision forging and CNC machining one-stop processing custom service factory

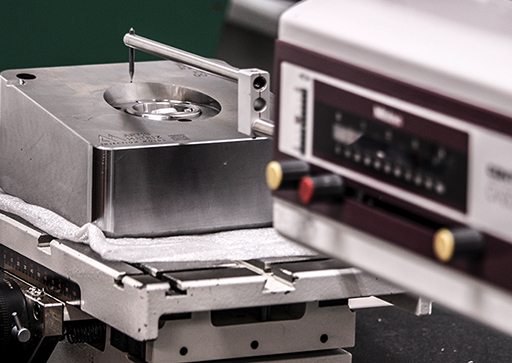

Advantages of CNC machining center

- Comprehensive functions of CNC machining centerCNC machining center is a kind of control processing machine tool with complete functions. It concentrates the functions of milling, boring, drilling, tapping and thread cutting on one device, so that it has multiple technological means. The machining center is equipped with a tool magazine, which stores different quantities of various tools or inspection tools, which are automatically selected and replaced by Cheng Xi during the machining process.

- The automation degree of CNC machining center is highAfter the workpiece is once clamped on the machining center, the digital control system can control the machine tool to automatically select and replace the tool according to different procedures, automatically change the machine tool spindle speed, feed rate, and the movement track of the tool relative to the workpiece and other auxiliary functions. Multi-process processing on several surfaces of the workpiece, and has multiple tool change or tool selection functions.

- The utilization rate of the CNC machining center is highThe advantages of automated processes such as process concentration and automatic tool change lie in reducing process time, improving work efficiency, and shortening production cycles, so that the cutting time can reach about 80% of the machine tool start-up time. It is suitable for small and medium-sized batch production with complex part shapes, high precision requirements, and frequent product replacement.

- The precision of CNC machining center is higherStable quality, high production efficiency in the case of multiple varieties and small batch production, which can reduce the time for production preparation, machine tool adjustment, and process inspection. Moreover, due to the use of the optimal cutting amount, the cutting time is reduced. It can also process complex surfaces that are difficult to process using conventional methods, and even some unobservable processing parts can be processed

- CNC machining has high efficiency, high machining precisionLow labor intensity, wide application, strong flexibility, and strong adaptability to different workpieces