-

Products suitable for forging process

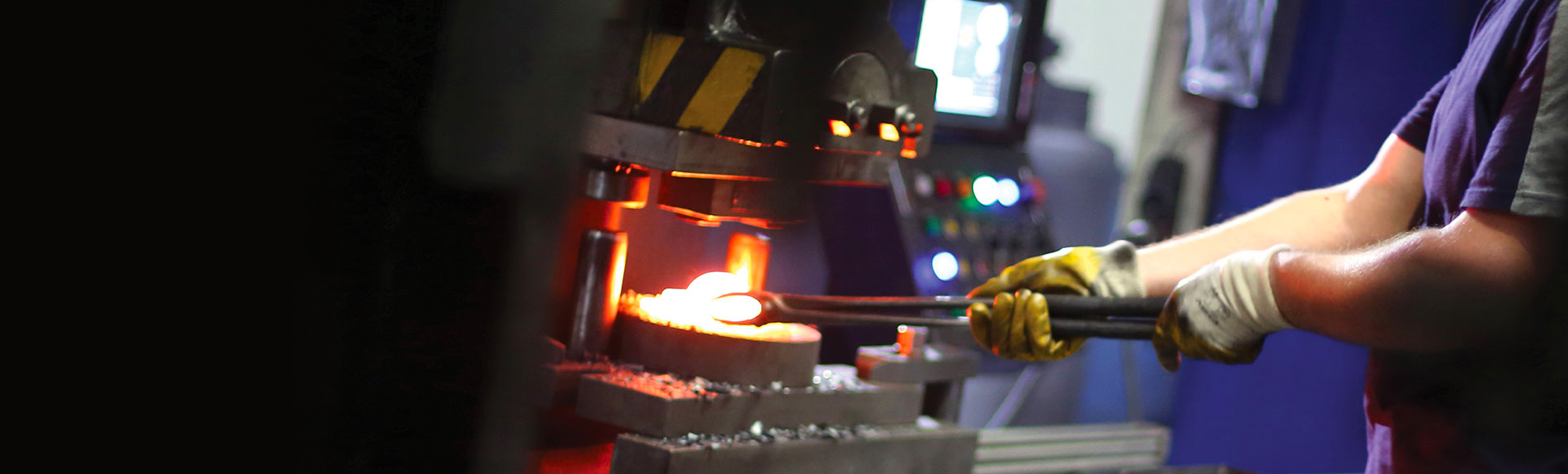

Forging is a processing method that uses forging machinery to apply pressure to metal blanks to cause plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes. It is one of the two major components of forging (forging and stamping). Forging can eliminate defects such as as-cast porosity produced in the metal smelting process and optimize the microstructure. At the same time, due to the preservation of complete metal flow lines, the mechanical properties of forgings are generally better than castings of the same material. For important parts with high loads and severe working conditions in related machinery, forgings are mostly used, except for plates, profiles or weldments that can be rolled with simple shapes. -

Products suitable for forging process

Among them, the process flow of hot die forging is the longest and the most complicated. The general sequence is: forging blanking - forging heating - roll forging preparation - die forging forming - trimming - punching - correction - intermediate inspection - inspection of the size of the forging and surface defects, heat treatment of forgings to eliminate tin stress, improve metal cutting performance, cleaning, mainly to remove surface oxide skin: correction, inspection, general forgings should go through appearance and hardness inspection, important forgings should go through chemical composition analysis, Inspection of mechanical properties, residual stress, etc.

Features of hot forging

Based in China, Serve the world

- Improve the internal structure of the metal, improve the mechanical properties of the metal

- Improve the hardness and strength of the product

- Adapt to a wide range. The quality of forgings ranges from less than 1kg to hundreds of tons

- Using precision die forging can make the size and shape of the forgings close to the finished parts

production process

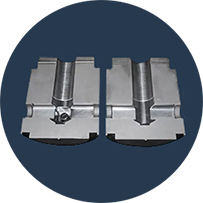

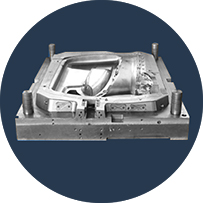

Mold design

Mold making

Preparation of raw materials

Forging and cutting edge

Heat treatment

Ballasting

Packaging and shipping

Surface treatment

Drilling and tapping

Vibratory grinding

Deburring

CNC machining