Incoming material inspection 01

Dimensional inspection: inspect its length, width, thickness and other parameters. Tensile test: test key parameters such as strength, toughness and elongation at break of the material. Hardness testing: judging the mechanical strength and wear resistance of materials

Size inspection

Pull test

Hardness testing

-

02

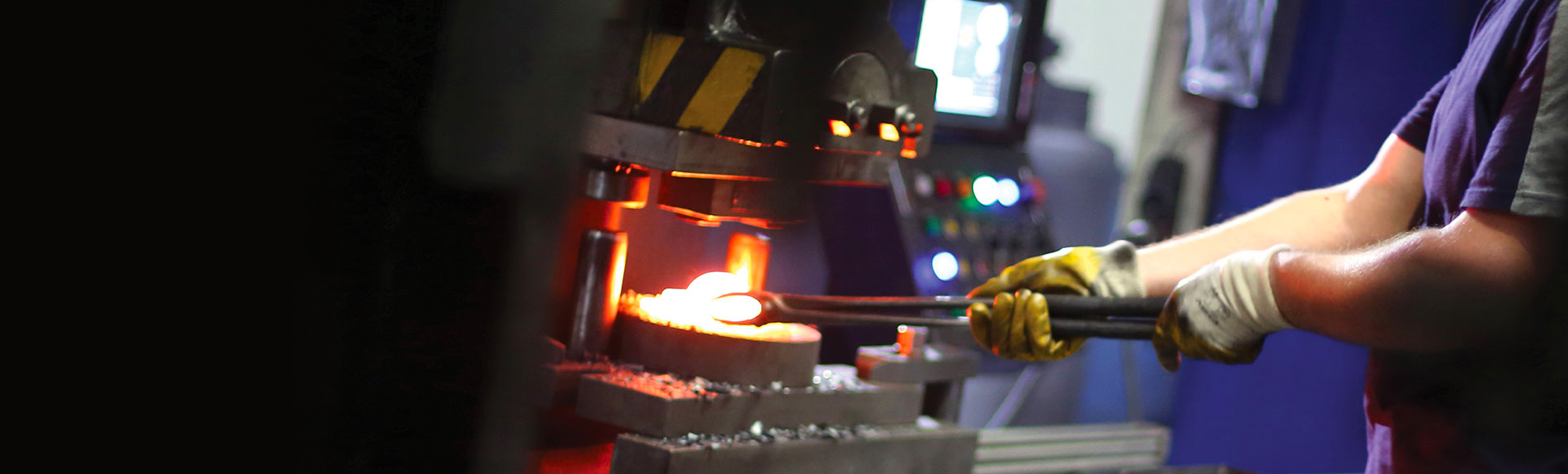

02Process inspection (IPQC inspection)

Find problems in time, control the production process, improve production efficiency, establish an early warning mechanism and improve the production process, and improve product quality and corporate competitiveness -

03

03Process Appearance Inspection

Visual inspection, optical inspection, lighting inspection and high-resolution image inspection, etc., record and analyze the inspection results to ensure that the product appearance quality meets customer requirements -

04

04Salt spray test of anodized products

Surface treatment, increase the hardness, wear resistance and corrosion resistance of the metal surface, salt spray test to ensure that the corrosion resistance meets customer requirements -

05

05Shipment inspection (OQC inspection)

Comprehensive product inspection and measurement, including appearance inspection, size inspection, packaging inspection