Development trend of precision forging and forming process

Precision forging and forming technology (net forming) refers to the forming technology that requires only a small amount of processing or no more processing after the parts are forged and formed to meet the requirements of the parts. Precision forging and forming technology is an important part of advanced manufacturing technology, and is also a widely used part manufacturing process in the automotive, mining, energy, construction, aviation, aerospace, weapons and other industries. Precision forging and forming technology not only saves materials and energy, reduces processing procedures and equipment, but also significantly improves productivity and product quality, reduces production costs, and thus improves the market competitiveness of products.

After more than 30 years of development, precision forging and forming technology has been developed rapidly and numerous research results have been achieved. In this paper, we summarize the development of precision forging and forming technology in recent years from five aspects, such as process methods, equipment, dies, forming process simulation and process optimization, and provide an outlook on the future development direction of precision forging and forming technology.

1、Precision forging process method

At present, many precision forging processes have been applied to production. According to the different forming temperature can be divided into hot precision forging, cold precision forging, warm precision forging, composite precision forging, isothermal precision forging, etc.

1.1 Hot finishing forging process

Forging temperature above the recrystallization temperature of precision forging process is called hot precision forging. Hot finishing forging material deformation resistance is low, plasticity is good, easy to form more complex workpiece, but because of strong oxidation, the workpiece surface quality and dimensional accuracy is low. The common process method of hot finishing forging is closed die forging. Due to the inaccuracy of the material, insufficient precision of die design and manufacturing, the deformation resistance of the final closing stage of the closed die forging is very large, which causes large damage to the equipment and die.

The common method to solve this problem is the principle of shunt pressure reduction, that is, to set up a shaped and reasonably sized shunt pressure reduction cavity hole in the last filled place of the closed cavity. When the cavity is completely filled, the excess metal of the billet is extruded from the shunt cavity hole, which solves the contradiction that the volume of the billet and the volume of the cavity cannot be strictly equal, and at the same time reduces the internal pressure of the cavity, which helps to improve the mold life.

As early as the 1950s, due to the lack of sufficient gear processing machine tools, the Germans began to use the closed hot-die forging method trial production of straight bevel gears. The development and application of hot forging gear technology in China started in the early 1970s, mature in the mid to late 1980s.

In 1970, the Shanghai Institute of Mechanization Technology and Shanghai Automobile Gear Factory cooperation, the United States Avenue T234 automobile differential planetary gears for hot finishing forging process forming test, and in 1973 to invest in the establishment of precision forging workshop, mass production [; 1980s, Shandong University to carry out the bevel gear precision forging process research and development, and industrialization. Due to the remarkable economic benefits, the hot finishing forging process has gained wide application in recent years.

1.2 Cold finishing forging process

Cold finishing forging is a precision forging process carried out at room temperature. Cold finishing forging process has the following characteristics: the shape and size of the workpiece is easier to control, avoiding the errors brought about by high temperature; the workpiece has high strength and precision, and good surface quality. In the process of cold forging and forming, the plasticity of the workpiece is poor, the deformation resistance is high, the requirements for the die and equipment are high, and it is difficult to form parts with complex structure. In order to overcome the problems of high deformation resistance and poor filling effect of cold and finish forging forming process, some new process methods have been developed one after another, mainly including closed plug forging, floating concave die forging, prefabricated shunt forging, etc.

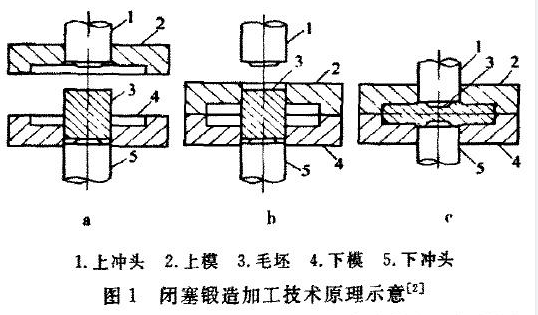

Occlusion forging is a one-way or opposing extrusion of metal in a closed die with one or two punches. The upper and lower dies used in the closed forging process technology are combined parts, consisting of upper concave die, upper punch, lower concave die, and lower punch, respectively. In the forging and forming process, the upper and lower concave dies are first closed to form a closed die cavity, while sufficient pressure is applied to them, and then the upper and lower punches are used to extrude and form the billet in the die chamber (as shown in Figure 1). In the forging process, the billet is in a state of strong three-way compressive stress, with good plasticity, and can form complex-shaped parts at one time with high production efficiency, and the metal flow line is continuously distributed along the shape of the forging, and the mechanical properties of the forging are good.

In floating die forging technology, the die is not fixed, but floats as the forging process proceeds. This design reduces the relative velocity between the die and the metal deformer and reduces the influence of friction on the contact surface, which improves the filling performance of the forging and reduces the deformation resistance.

By setting up an overflow port at a certain position of the forging, the material is always free to flow in the process of filling the cavity, thus improving the cavity filling and reducing the deformation resistance and processing load. In order to improve the filling situation of precision forging of straight cylindrical gears, Qingping Zhang et al. proposed the process method of pre-forging with a diversion hole and a diversion forging. The process method pre-forging upper die and lower die with tabs, forging a shunt area in the center part of both ends of the billet; in the final forging, the center shunt area plays the role of shunting the material, improving the flow state of the material, thus reducing the forming load and improving the filling of the billet.

In recent years, the cold forging process has gained some development in China. Tico Intelligent Equipment Co., Ltd. has introduced advanced forging machines and die processing equipment, and is currently the forefront of cold forging equipment conditions in China. The total annual output of various types of precision cold and warm forgings for automobiles and motorcycles reaches 4000t. Some typical high difficulty cold forgings such as car isochronous universal joint jacket, star sleeve, transmission drive shaft, etc., have been mass produced in the plant.

1.3 Warm finishing forging process

Warm precision forging is a precision forging process carried out at a suitable temperature under the recrystallization temperature. Warm forging precision forming technology not only breaks through the cold forging forming deformation resistance, the shape of the part can not be too complex, the need to increase the intermediate heat treatment and surface treatment step limitations, but also overcome the hot forging due to strong oxidation and reduce the surface quality and dimensional accuracy of the problem. It has the advantages of cold forging and hot forging at the same time, to overcome the shortcomings of the two. However, the warm forging process has low forging temperature, narrow forging temperature range and more stringent requirements for its forging range, requires high-precision specialized equipment, and has high requirements for die structure and die material.

1.4 Composite forging process

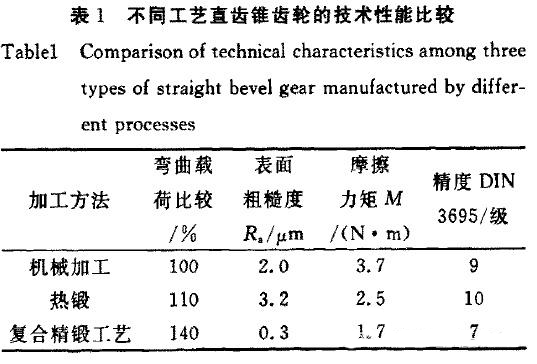

With the increasing complexity and precision requirements of precision forging workpieces, the simple cold, warm and hot forging process can no longer meet the requirements. Compound fine forging process will be cold, temperature, hot forging process to combine together to complete a workpiece forging, can play the advantages of cold, temperature, hot forging, abandon the shortcomings of cold, temperature, hot forging. Table 1 shows the comparison of the technical properties of straight bevel gears produced by three different process methods, from which it can be seen that the mechanical properties, dimensional accuracy, and surface roughness of the workpiece produced by the composite finish forging process have been improved compared with the other two processes []. Therefore, the composite finish forging process is an important direction for the development of the current finish forging process.

1.5 Isothermal finish forging process

Isothermal finish forging refers to the die forging and forming of the billet at a temperature that tends to be constant. In order to ensure the constant temperature forming conditions, the die must also be heated to the same temperature as the billet. Isothermal die forging is commonly used in the aerospace industry for precision forming of titanium alloys, aluminum alloys, magnesium alloys and other hard-to-deform materials, and in recent years it is also used for precision forming of non-ferrous metals in the automotive and mechanical industries.

Isothermal forging is mainly applied to metal materials with narrow forging temperature, especially titanium alloy which is very sensitive to deformation temperature. Isothermal forging parts generally have a thin web, high tendons and thin walls, such parts billet heat is quickly absorbed by the die, the temperature drops rapidly, using ordinary forging methods, not only need to significantly increase the tonnage of equipment, but also easy to cause cracking of the die.

1.6 The development trend of precision forging process

With the development of the manufacturing industry, the requirements for precision forging formed parts are getting higher and higher, and also put forward higher requirements for the research and development of precision forging process, the current main direction of precision forging process research are as follows.

1) Continuous process innovation. In order to meet the requirements of forming parts and reduce production costs, it is necessary to continuously develop a new precision forging forming process with high forming accuracy, long die life and high production efficiency.

2) The development of composite processes. With the increasing requirements of forming parts process, a single precision forging is difficult to meet the requirements, which requires the development of composite forming process, the combination of different temperatures or different process methods of forging process to complement each other's strengths and weaknesses to complete a part of the processing and manufacturing. Precision forging process can also be combined with other precision forming processes such as precision casting, precision welding and other processes to improve the application range and processing capabilities of precision forming processes.

3) Knowledge-based process design. With the continuous development of precision forging process, process design is becoming increasingly complex, in order to improve the reliability and efficiency of process design, the development of knowledge-based expert system is an important research direction for future precision forging process design.